TMA 4000 SE can be applied to:

Linear expansion and contraction, coefficient of thermal expansion (1/K)

• Volume expansion and contraction

Glass transition temperature (Tg)

• Softening temperature (Ts)

• Explosion temperature and explosion time

Expansion and contraction of powders and films

Thermal performance analysis of thermoplastic materials

Curing and Performance Analysis of Thermosetting Materials

Technical parameters of TMA 4000SE thermal mechanical analyzer:

• Temperature range:- 150 … 600°C

Heating rate: 0... 20 ° C/min

• Displacement range: ± 2500 μ m

• Displacement resolution: 2.5nm

• Stress range: 4.9N (0.98mN step size)

• Stress modes: compression/needle insertion, bending, tension

• Measurement atmosphere: oxidation, inertness, vacuum

• Refrigeration system: liquid nitrogen (optional)

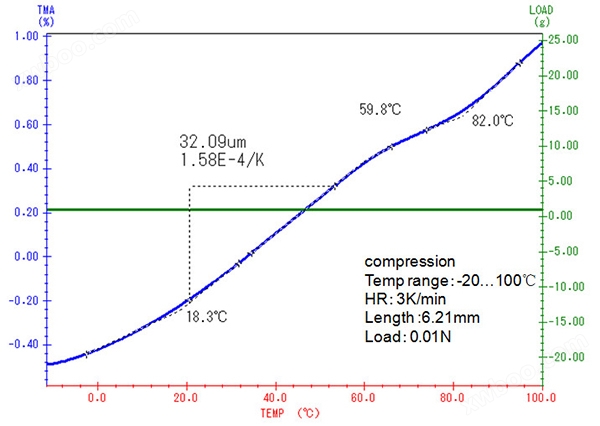

Epoxy resin - expansion measurement

The sample undergoes a linear expansion process before approximately 60 ° C, with an expansion coefficient of 1.58 × 10-4 1/K. After 60 ° C, the sample undergoes glass transition and the coefficient of expansion changes.

Natural Spider Silk - Stretching Measurement

The spider silk sample measured in the picture has a diameter of only 1um.

Multilayer film samples - needle in measurement

In needle insertion mode, the two-layer film sample showed a two-stage needle insertion process. After penetrating one layer, the dL curve of the single-layer film sample has flattened.

Resin curing test

The test is conducted in the form of oscillatory force. Compared to 25 ° C, 56 ° C has a lower initial viscosity and larger amplitude of the sample; But solidification occurs earlier, and as solidification occurs, the amplitude rapidly decreases.

Epoxy resin - fixed deformation testing

As the temperature increases, the natural expansion trend of the sample becomes larger, and the force required to maintain a fixed compression deformation also increases accordingly. It is not until the sample undergoes glass transition from 58 ° C that the modulus of the sample decreases and the required load force decreases accordingly.

Polyimide - Measurement of Expansion under Humidity Atmosphere

The blue TMA curve in the figure not only displays the corresponding thermal expansion of the sample as the constant temperature increases (from 20 ° C to 85 ° C), but also shows the corresponding hygroscopic expansion process as the ambient humidity increases (from 5% to 70%, 85% relative humidity).